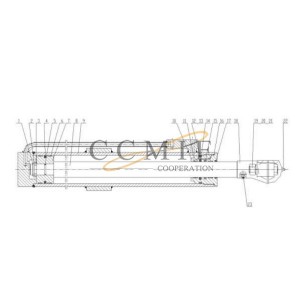

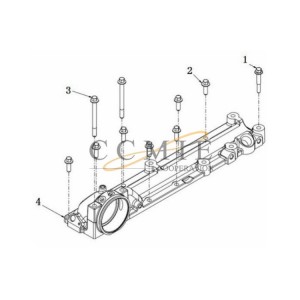

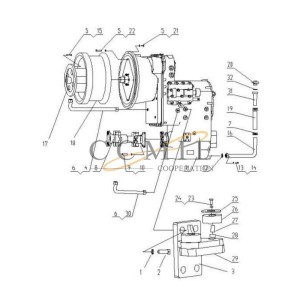

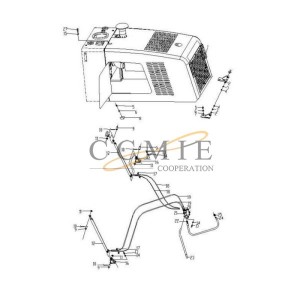

Umqhubi weshafti XCMG Liugong motor grader iinxalenye spare

Ishafti yomqhubi

Kuba zininzi iintlobo zeendawo ezisecaleni, asikwazi ukuzibonisa zonke kwiwebhusayithi. Nceda uzive ukhululekile ukuqhagamshelana nathi ukuze ufumane ezinye.

Inzuzo

1. Sinikezela ngeemveliso zoqobo kunye nezasemva kwentengiso kuwe

2. Ukusuka kumvelisi ukuya kumthengi ngokuthe ngqo, ukugcina iindleko zakho

3. Isitokhwe esizinzileyo seendawo eziqhelekileyo

4. Ngexesha lokuHanjiswa kweXesha, kunye neendleko zokuthumela ezikhuphisanayo

5. Ubungcali kunye nexesha emva kwenkonzo

Ukupakisha

Iibhokisi zeebhokisi, okanye ngokwesicelo sabathengi.

inkcazelo

I-Driver-shaft yenye yeendawo eziphambili zecandelo lokuqhuba le-chassis yoomatshini bokwakha. Iphantsi kokugoba okunzima, imithwalo ye-torsional kunye nemithwalo yempembelelo enkulu ngexesha lokusetyenziswa, efuna ukuba i-semi-shaft ibe namandla aphezulu okukhathala, ubunzima kunye nokumelana nokunxiba kakuhle. Ubomi benkonzo ye-semi-shaft abuchaphazeli nje kuphela isicwangciso kunye nokukhethwa kwezinto eziphathekayo kwinqanaba loyilo lwemveliso, kodwa kunye nenkqubo yokuvelisa imveliso kunye nokulawulwa komgangatho we-forgings nazo zibaluleke kakhulu.

Inkqubo yohlalutyo lomgangatho kunye namanyathelo okulawula kwinkqubo yokuvelisa

1 Inkqubo yokusika

Umgangatho wokuvala uya kuchaphazela umgangatho wokulandela simahla izikhewu ezingenanto kunye nokuba kufa ukwenza izinto. Iziphene eziphambili kwinkqubo yokungabi nanto zezi zilandelayo.

1) Ubude bungaphandle kokunyamezela. Ubude be-blanking bude kakhulu okanye bufutshane kakhulu, ixesha elide linokubangela ukuba i-forgings ibe yinto efanelekileyo kakhulu kubungakanani kunye nempahla yenkunkuma, kwaye imfutshane kakhulu inokubangela ukuba i-forgings inganeliseki okanye incinci ngobukhulu. Isizathu sinokuthi i-baffle yokumisa imiselwe ngokungalunganga okanye i-baffle yokumisa ikhululekile okanye ayichanekanga ngexesha lenkqubo yokuvala.

2) I-slope yobuso besiphelo bukhulu. Ukuthambeka komphezulu wesiphelo esikhulu kuthetha ukuba ukuthambekela komphezulu wesiphelo sendawo engenanto ngokunxulumene ne-longitudinal axis idlula ixabiso elivumelekileyo elichaziweyo. Xa i-slope yobuso besiphelo bukhulu kakhulu, ukugoba kunokwakheka ngexesha lenkqubo yokubumba. Isizathu sinokuthi ibha ayinyanzelwanga ngexesha lokugquma, okanye incam yezinyo ye-band saw blade inxibe ngokungaqhelekanga, okanye i-band saw blade tension incinci kakhulu, ingalo yesikhokelo somatshini wokusarha ayifani. umgca othe tye, njalo njalo.

3) Burr kwisiphelo sobuso. Xa usarha imathiriyeli yebha, i-burrs idla ngokuthanda ukubonakala kwikhefu lokugqibela. Izikhewu ezineebhula kusenokwenzeka ukuba zibangele ukutshisa okugqithisileyo kwengingqi kunye nokutshisa kakhulu xa kushushu, kwaye kulula ukugoba kunye nokuqhekeka ngexesha lokubumba. Esinye isizathu kukuba isarha iyaluphala, okanye amazinyo asarha agugile, awabukhali ngokwaneleyo, okanye isarha samazinyo aphukileyo; okwesibini kukuba isantya somgca wesarha asimiselwanga kakuhle. Ngokubanzi, isarha entsha inokukhawuleza, kwaye isarha endala iyacotha.

4) Ukuqhekeka kwisiphelo sobuso. Xa ubunzima bezinto eziphathekayo bungalingani kwaye ulwahlulo lwezinto eziphathekayo lunzulu, kulula ukuvelisa isiphelo sokuqhekeka kobuso. Kwiindawo ezingenanto kunye nokuqhekeka kokuphela, ukuqhekeka kuya kwandiswa ngakumbi ngexesha lokukhwabanisa.

Ukuze kuqinisekiswe umgangatho wokugquma, la manyathelo olawulo alandelayo athathiweyo ngexesha lenkqubo yokuvelisa: ngaphambi kokuvala, qinisekisa uphawu lwezinto eziphathekayo, ukucaciswa, ubuninzi, kunye nenombolo yesithando somlilo (ibhetshi) ngokuhambelana nemigaqo yenkqubo kunye namakhadi enkqubo. . Kwaye ujonge umgangatho womgangatho weentsimbi ezijikelezayo; i-blanking iqhutyelwa kwiibhetshi ngokwenombolo yokubumba, i-brand yezinto eziphathekayo, inkcazo kunye nenombolo yokunyibilika kwesithando somlilo (i-batch), kunye nenani lezinto ezingenanto zibonakaliswe kwikhadi lokulandelela ukujikeleza ukukhusela ukuxubana kwezinto zangaphandle; Xa usika izinto eziphathekayo, inkqubo "yokuhlola kuqala", "ukuzihlola" kunye "nokuhlola i-patrol" kufuneka isetyenziswe ngokungqongqo. Ukunyamezela kwe-dimensional, i-end slope kunye ne-end burr ye-blank kufuneka ihlolwe rhoqo ngokweemfuno zenkqubo, kwaye uhlolo lufanelekile kwaye imo yemveliso imakishwe. Umyalelo ungatshintshwa emva koko; ngexesha lenkqubo yokuvala, ukuba ii-blanks zifunyenwe zinee-folds, izibazi, ukuqhekeka kokuphela kunye nezinye iziphene ezibonakalayo, kufuneka zixelelwe kumhloli okanye ochwephesha ukuze zilahlwe ngexesha; indawo yokugquma kufuneka igcinwe icocekile, inamabakala ahlukeneyo ezinto kunye nenombolo yokunyibilikisa I-Furnace (ibhetshi), iinkcukacha kunye nemilinganiselo kufuneka zibekwe ngokwahlukileyo kwaye ziphawulwe ngokucacileyo ukuphepha ukuxuba. Ukuba kufuneka ukutshintshwa kwezinto eziphathekayo, iinkqubo zokuvunywa kokutshintshwa kwezinto eziphathekayo mazilandelwe ngokungqongqo, kwaye izinto eziphathekayo zinokukhutshwa kuphela emva kokuvunywa.

2 Inkqubo yokufudumala.

Inkqubo yokuvelisa i-semi-shaft ifudunyezwa yimililo emibini, i-billet ye-forging yamahhala ifudumeza isithando somlilo segesi, kwaye i-die forging ifudumala ngesithando sombane sombane, ngoko ke ukulawulwa kokuthintela ukulandelelana kokufudumeza kunzima kwaye kunzima; ukuze siqinisekise umgangatho wokufudumeza, senze le migaqo yomgangatho ilandelayo:

Xa isitofu segesi sifudumala, akuvumelekanga ukuhlawula ngokuthe ngqo izinto kwindawo yokushisa ephezulu, kwaye akuvumelekanga ukutshiza ilangatye ngqo phezu kwendawo engenanto; xa ufudumeza kwisithando sombane, indawo engenanto akufanele ingcoliswe ngeoli. Iimpawu zokufudumeza ziya kuphunyezwa ngokweemfuno zemimiselo ehambelanayo yenkqubo yokuqulunqa, kunye nokushisa kokushisa kwe-5-10 iziqwenga ezingenanto kuya kuqinisekiswa ngokupheleleyo phambi kokutshintsha ukubonisa ukuba iiparamitha zokufudumeza zizinzile kwaye zithembekile. I-billet ayinakwenziwa ngexesha ngenxa yezixhobo kunye neengxaki zezixhobo. Inokucutshungulwa ngokupholisa okanye ngaphandle kwesithando somlilo. I-billet etyhidiweyo kufuneka imakishwe kwaye igcinwe ngokwahlukileyo; i-billet inokufudumeza ngokuphindaphindiweyo, kodwa inani lokufudumeza alikwazi ukudlula amaxesha ama-3. Ubushushu bezinto eziphathekayo xa i-blank ifudumala kufuneka ihlolwe ngexesha langempela okanye rhoqo nge-thermometer ye-infrared, kwaye irekhodi lokushisa kufuneka lenziwe.

3 Inkqubo yokwenza ibhilethi.

Iziphene eziqhelekileyo ngexesha lokwenziwa kwe-billet ziquka ububanzi obugqithisileyo okanye ubude bentonga ye-billet ephakathi, iimpawu zehamile ezingaphezulu, kunye nokuguquka kwenyathelo elibi. Ukuba ububanzi bentonga bulungile kakhulu, kuya kuba nzima ukuyifaka kwi-cavity ngexesha lokufa. Ukuba intonga incinci encinci, i-coaxiality ye-forging ingaba yimbi kakhulu ngenxa yesithuba esikhulu sentonga ngexesha lokufa; Iimpawu zehamile yomphezulu kunye notshintsho olubi lwenyathelo lunokubakho Ukukhokelela kwimingxuma okanye ukugotywa kumphezulu wokwenziwa kokugqibela.

4 Die forging kunye nenkqubo yokucheba.

Iziphene eziphambili kwi-semi-shaft die forging process ziquka ukugoqa, ukugcwaliswa okunganeleyo, ukunyanzeliswa (ukungabetheki), ukungahambi kakuhle kunye nokunye.

1) Songa. Ukugotywa kwe-semi-shaft kuqhelekile kwisiphelo sobuso be-flange, okanye kwi-fillet yesinyathelo okanye phakathi kwe-flange, kwaye ngokuqhelekileyo i-arc-shaped okanye i-semi-circular. Ukubunjwa komqolo kuhambelana nomgangatho wesithuba esingenanto okanye esiphakathi esingenanto, uyilo, ukuveliswa kunye nokuthambisa isikhunta, ukuqina kokubumba kunye nehamile, kunye nokusebenza kwangempela kokubumba. Ukusonga ngokubanzi kunokujongwa ngeliso lenyama xa ukubunjwa kukwimo ebomvu eshushu, kodwa ngokuqhelekileyo kunokudlula uhlolo lwamasuntswana omlingo kwinqanaba lamva.

2) Ngokuyinxenye ezaliswe kukunganeliseki. Ukunganeliseki kwenxalenye ye-semi-shaft forgings ikakhulukazi kwenzeka kwiikona zangaphandle ezijikelezayo zentonga okanye i-flange, ebonakaliswa njengoko iikona ezijikelezileyo zikhulu kakhulu okanye ubukhulu abuhambisani neemfuno. Ukunganeliseki kuya kukhokelela ekunciphiseni isibonelelo somatshini wokubumba, kwaye xa kunzulu, ukuqhutyelwa phambili kuya kuchithwa. Izizathu zokunganeliseki zinokuthi: uyilo lwe-billet ephakathi okanye olungenanto alunangqiqo, ububanzi okanye ubude bayo abufanelekanga; ubushushu bokubumba buphantsi, kwaye ubumanzi besinyithi bubuthathaka; ukuthanjiswa kwefayidi yokubunjwa akwanelanga; ukuqokelelana kwesikali se-oxide kwindawo yokufa, njl.

3) Ukungahambi kakuhle. Ukungahambi kakuhle kukufuduswa kwesiqingatha esiphezulu sokubumba ngokumalunga nesiqingatha esisezantsi ecaleni kwendawo yokwahlula. Ukubekwa endaweni engafanelekanga kuya kuchaphazela ukuma koomatshini, okukhokelela kwisibonelelo soomatshini sasekhaya esinganelanga. Izizathu zinokuthi: umsantsa phakathi kwentloko yehamile kunye nomzila wesikhokelo mkhulu kakhulu; uyilo lomsantsa wokuvala idiyidi yokugoba akukho ngqiqweni; ukufakwa kokungunda akulunganga.

5 Inkqubo yokucheba.

Esona siphene somgangatho kwinkqubo yokucheba yiflash enkulu okanye engalinganiyo eshiyekileyo. Isibane esikhulu okanye esingalinganiyo esishiyekileyo sinokuchaphazela ukuma komatshini kunye nokubamba. Ukongeza kokunyuka kwesibonelelo somatshini wendawo, kuya kubangela ukutenxa komatshini, kwaye kunokubangela ukusika ngenxa yokusika okuphakathi. Isizathu sinokuba: i-punch ye-trimming die, i-gap of die ayilwanga kakuhle, okanye i-fay igugile kwaye ikhulile.

Ukuze kuthintelwe iziphene ezikhankanywe ngasentla kunye nokuqinisekisa umgangatho wokukhwabanisa, siye saqulunqa kwaye samkela uluhlu lwamanyathelo okuthintela nokulawula: ukugqiba ubungakanani obungenanto okanye obuphakathi obungenanto ngokuphononongwa koyilo kunye nokuqinisekiswa kwenkqubo; Kuyilo lokungunda kunye nenqanaba lokuqinisekisa, ngaphandle kokungunda okuqhelekileyo Ukongeza kuyilo lomngxunya, ibhulorho kunye noyilo lwesilo, ingqalelo ekhethekileyo ihlawulwe kwiifayili zenyathelo kunye nokutshixa izikhewu ukuthintela ukusongwa kunye nokutshintsha kakubi, ulawulo olungqongqo lwekhwalithi yenkqubo. ukugquma, ukufudumeza, kunye neebhilidi zokubumba zamahhala, kwaye ugxininise kwi-oblique surface ye-billet. Idigri kunye ne-burrs ebusweni bokugqibela, ukutshintshwa kwenyathelo le-billet ephakathi, ubude bentonga, kunye nobushushu bezinto eziphathekayo.

Indawo yethu yokugcina impahla1

Pakisha kunye nenqanawa

- I-Aerial Boom Lift

- Ilori yokulahla i-China

- I-Recycler ebandayo

- I-Cone Crusher Liner

- Isingxobo Side Lifter

- Inxalenye ye-Dadi Bulldozer

- I-Forklift Sweeper Attachment

- Izahlulo ze-Bulldozer ze-Hbxg

- Iinxalenye zeNjini yeHowo

- Hyundai Excavator Hydraulic Pump

- Iinxalenye zeKomatsu Bulldozer

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Izahlulo zeBulldozer yaseLiugong

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Amacandelo eNjini yaseShacman

- Shantui Bulldozer Clutch Shaft

- I-Shantui Bulldozer iQhagamshela i-Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- I-Bulldozer ye-Shantui Bulldozer yokuPhakamisa iKit yokuLungisa iSilinda

- Amacandelo e-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- IShantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- I-Shantui Dozer Tilt Cylinder Kit yokulungisa

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- I-Shantui Sd22 Ethwele umkhono

- I-Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Iinxalenye zeNjini yeSinotruk

- Ilori yokutsala

- Izahlulo ze-Bulldozer ze-Xcmg

- Xcmg Bulldozer izahlulo eziSpare

- Xcmg Hydraulic Lock

- Ugqithiso lwe-Xcmg

- Amacandelo eNjini yeYuchai