Shantui Bulldozer ukulungiswa

Iinxalenye ze-Shantui Bulldozer

1. Ayinakuqalisa

Ibulldozer ayikwazanga ukuqalisa ngexesha lokukhutshwa kwe-hangar.

Emva kokuphelisa imeko yokungabikho kombane, i-fuel, i-loose okanye i-blocked tank ye-tank joints, njl., ekugqibeleni kwakrokrelwa ukuba i-PT fuel pump yayingasebenzi kakuhle. Jonga isixhobo sokulawula umoya kunye namafutha. Emva kokuvula umbhobho wokungena kunye nokusebenzisa i-compressor yomoya ukubonelela umoya kumbhobho wokungena, umatshini unokuqalisa kakuhle. Ukuba ukunikezelwa komoya kumisiwe, umatshini uya kucima ngokukhawuleza. Ngoko ke, kuchongwa ukuba isixhobo sokulawula umoya kunye nepetroli asisebenzi kakuhle.

Khulula isixhobo sokulawula amafutha entongomane, jija isixhobo sokulawula amafutha e-AFC ngasekunene nge-Allen wrench, uze uqinise i-nut yokulungisa. Xa umatshini uqaliswa kwakhona, unokuqalisa ngokuqhelekileyo kwaye impazamo iyanyamalala.

2. Ukungaphumeleli kwenkqubo yokubonelela ngamafutha

I-bulldozer kufuneka ikhutshwe kwi-hangar ngexesha lokugcinwa kwexesha, kodwa ayikwazi ukuqhutyelwa.

Khangela itanki yamafutha, i-fuel yanele; vula iswitshi kwindawo engezantsi yetanki yamafutha, kwaye iya kucima ngokuzenzekelayo emva komzuzu we-1 wokuqhuba; sebenzisa umbhobho wokucoca ukungenisa ukudibanisa ngokuthe ngqo itanki yamafutha kumbhobho wamafutha wempompo ye-PT. ; Qinisa isikrufu semanuwali sevalve ye-solenoid yokusikwa kwe-oyile kwindawo evulekileyo, kodwa ayikaqalwa.

Xa ufaka isihluzo kwakhona, vula i-tank ye-fuel switch 3 ~ 5 ukujika, kwaye ufumane inani elincinci lepetroli eliphuma kumbhobho wokucoca, kodwa i-fuel iya kuphelelwa emva kwexesha. Emva kokuqwalaselwa ngokucophelela kunye nokuthelekisa ngokuphindaphindiweyo, ekugqibeleni kwafunyaniswa ukuba i-tank ye-fuel switch ayizange ivulwe. Ukutshintsha kunesakhiwo esingqukuva. Xa ijika i-90 °, i-oyile yesiphaluka idibaniswe, kwaye xa ijika i-90 °, i-oil circuit iyanqunyulwa. Umtshini wevalve yebhola awunamqheba kwaye akukho sixhobo somda, kodwa intloko yesikwere yentsimbi ibonakalisiwe. Umqhubi uye wasebenzisa ngempazamo iswitshi yevalve yebhola njengokutshintsha kwe-throttle. Emva kokuguqula i-3 ukuya kwi-5, ivalve yebhola ibuyele kwindawo evaliweyo. Ngethuba lokujikeleza kwe-valve yebhola, nangona ixabiso elincinci le-fuel lingena kwisiphaluka se-fuel, sinokuqhutyelwa kuphela ngomzuzu we-1. Xa i-fuel kwipayipi iphelile, umatshini uya kucima.

3. Ukuvuza kweoli kwi-winch

Ngexesha lokwakhiwa kwebulldozer, ukuvuza kwe-oyile kwenzeka kwiwintshi yentambo yocingo. Emva kokukhupha zonke iintambo zocingo, kwafunyaniswa ukuba ioli ye-hydraulic ivuza kwiibholithi kwisihlalo se-winch, kwaye xa i-throttle yanda, ukuvuza kwakuhamba ngokukhawuleza, kwaye kwakungekho phantse ioli evuzayo xa idling.

Uhlalutyo lwangaphambili lunokubangelwa yi-bolts evulekileyo okanye i-gaskets eyonakalisiweyo, kodwa emva kokutshintsha i-gaskets kunye nokuqinisa i-bolts, uvavanye umatshini, iphutha lihlala. Uhlalutyo olongezelelweyo lomzobo we-hydraulic schematic diagram lubonisa ukuba isizathu sinokuba yimbuyekezo ye-oyile embi kunye noxinzelelo olukhulu lwangasemva. Ngoko ke, umbhobho wokubuyisela i-oyile osuka kwi-winch ukuya kwivalvu yokulawula watshintshwa, oko kukuthi, umbhobho omfutshane wokubuyiswa kwe-oyile wawudityanisiwe ukuya kwindawo engasentla yetanki yamafutha, wathatyathelw' indawo ngombhobho owawungqindilili kune-oyile yokuqala. umbhobho wokubuyisela ukwenzela ukuba ukuphela kombhobho wokubuyisela i-oyile kungaxhunywanga kwi-valve yokulawula. Qhagamshela ngokuthe ngqo umbhobho omfutshane wokubuya kwe-oyile ukunciphisa uxinzelelo lwe-oyile ngasemva. Zama umatshini kwakhona kwaye impazamo iyanyamalala.

4. Injini yobushushu ayikwazi ukuhamba

Ngexesha lokusetyenziswa, umatshini obandayo waqala kwaye i-bulldozing yayiyinto eqhelekileyo, kodwa emva kwemizuzu engama-50 yomsebenzi, ibulldozer yaba buthathaka kwaye iyancipha njengoko ubushushu be-oyile bukhula ngokuthe ngcembe, kwaye kwakunzima nokuhamba phantsi komthwalo. Ukuba uyeka kwaye uphumle iiyure ezi-2 ngeli xesha, qalisa injini kwakhona emva kokuba ubushushu be-oyile buyehla, kwaye ukuqala kunye ne-bulldozing kuya kubuyela kwisiqhelo.

Ngexesha lokusebenza, i-throttle ye-injini ayizange iyancipha kwaye isantya asizange sinciphise, nto leyo ebonisa ukuba ubuthathaka be-bulldozer abunanto yakwenza injini. Uhlalutyo lwangaphambili lukholelwa ukuba imbangela yokungabikho kweoli kwi-converter torque, ukuvinjelwa kwesiphaluka seoli okanye ukungaphumeleli kokuhanjiswa okanye i-clutch yokulawula.

Khangela ukuba isiguquli setorque siqhelekile; khulula i-vent screw kwisantya esiguquguqukayo sokucoca okulungileyo, kwaye kufunyenwe ukuba kukho amaqamza kwi-oyile ekhutshiweyo, engenakuphelelwa ixesha elide. Uhlalutyo lukholelwa ukuba ukuba kukho indawo apho umoya ungena khona, zombini i-cooler kunye nokufudumala kufuneka kuhanjiswe emoyeni, okubangela ukuba umatshini usebenze ngokuqhelekileyo kwindawo ebandayo, kwaye kunokugqitywa ukuba i-oyile ephantsi yoxinzelelo ikwimeko efanelekileyo. . Ukungena komoya we-high-high-pressure oil circuit ye-injini yokushisa kubangela ukuba umatshini ungaphumeleli ukuhamba, okufuneka kubangelwe ngokugqithisileyo kwe-vacuum ye-oyile ephantsi yoxinzelelo.

5. I-bulldozing blade ayibaleki

Emva kokuqala injini, isixhobo sokulawula kunye ne-bulldozing blade ayizange iphendule. Qwalasela itanki yeoli yehydraulic kwaye ufumanise ukuba itanki yeoli ayinanto. Ngokokutsho komqhubi, itanki yeoli yehydraulic yagcwala phambi kokuba aphume emsebenzini kusuku lwayizolo. Ngoko ke, i-pan yeoli ye-injini ihlolwe kwaye inqanaba le-oyile lafunyanwa ukuba liyenyuka. Emva koko ipompo yeoli esebenzayo yasuswa ukuze ihlolwe, kwaye kwafunyaniswa ukuba uphawu lweoli olujikelezayo lwepompo yeoli esebenzayo lonakaliswe. Itanki yeoli yehydraulic ibekwe kwindawo ephezulu, ivumela i-oyile ukuba ingene kwi-oyile ye-oyile ye-injini ye-diesel ngokusebenzisa i-oyile ejikelezayo eyonakeleyo ngobusuku obunye. Xa ujongana nale meko, buyisela isitywini esitsha se-oyile kunye ne-oyile ye-injini, yongeza i-oyile yoxinzelelo, kwaye ukhuphe wonke umoya kwi-hydraulic system ukuze ibulldozer isebenze ngokuqhelekileyo.

6. Ayikwazanga ukuqalisa injini yedizili

Into yokucoca isihluzo sesibaso se-injini ivaliwe okanye umgca wamafutha uvaliwe. Kule meko, i-fuel filter element kufuneka ihlanjululwe okanye ithathelwe indawo entsha, kwaye umgca wepetroli kufuneka uhlambuluke ngexesha elifanayo.

Kukho amafutha kwi-cylinder. Jonga inqanaba lamafutha kwitanki yedizili. Ukuba isibaso ayonelanga, yongeza isibaso, coca umlomo wenaliti yesibaso okanye ufake entsha.

7. I-gearbox ayinakubandakanyeka kwisixhobo esithile

Iringi yokutywina yomqolo wepiston yebhokisi yegiya yonakele, kwaye isiphelo sobuso bomqolo weegiya zeplanethi sonakalisiwe. Ukuba oku kuyinyani, buyisela iphedi yokuphela okanye iringi yokutywina ufake entsha.

Inkqubo ye-lever ye-gearbox ayilungiswanga kakuhle okanye ikhululekile. Ukujongana nemeko enjalo, kuyimfuneko ukulungelelanisa kwakhona inkqubo ye-lever ye-gearbox.

8. Thintela umkhandi webulldozer ukuba anganxibi

Ukuxinana kwetsheyini kuya kuchaphazela ukutyibilika, uxinzelelo kunye nokukhuhlana phakathi kwamalungu omatshini wokubaleka webulldozer. Kuphela kuxa ukunyanzeliswa kwetyathanga kuphakathi apho ukunxitywa kwendlela yokuhamba kuncitshiswe kwaye ukungahambi kakuhle kwekhonkco kunokuthintelwa. Ke ngoko, ukuqina kwekhonkco kubaluleke kakhulu. Ukunyanzeliswa kwekhonkco kukhulu kakhulu, oko kwandisa uxinzelelo kunye nokuxhatshazwa phakathi kweendawo ezihambayo ezihambayo zendlela yokuhamba, kunye nokunyuka kwe-friction, isandi esiveliswayo sibukhali kwaye sinzima, esiqinisa ukunxiba. Ngokukodwa ikhonkco elidityanisiweyo kunye nevili, i-welded surface ayigudi, ibangela ukuba indawo yoqhagamshelwano phakathi kwamacandelo iyancipha kakhulu, ukwenzela ukuba ukunxiba kunokunyusa, okubangela ukuba i-roller iwelding layer kunye nekhonkco yekhonkco ixoke. . Iziganeko ezidweliswe ngasentla zinokubangela ukuba iindawo zifudumale ngenxa yokuguga, kwaye ekugqibeleni zikhokelela ekungaphumelelini kwangaphambi kwexesha lokutywinwa kwenxalenye nganye kunye nomonakalo kwiindawo.

Indawo yethu yokugcina impahla1

Pakisha kunye nenqanawa

- I-Aerial Boom Lift

- Ilori yokulahla i-China

- I-Recycler ebandayo

- I-Cone Crusher Liner

- Isingxobo Side Lifter

- Inxalenye ye-Dadi Bulldozer

- I-Forklift Sweeper Attachment

- Izahlulo ze-Bulldozer ze-Hbxg

- Iinxalenye zeNjini yeHowo

- Hyundai Excavator Hydraulic Pump

- Iinxalenye zeKomatsu Bulldozer

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Izahlulo zeBulldozer yaseLiugong

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Amacandelo eNjini yaseShacman

- Shantui Bulldozer Clutch Shaft

- I-Bulldozer ye-Shantui idibanisa i-Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

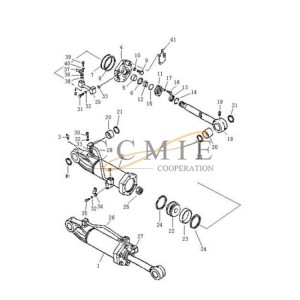

- I-Bulldozer ye-Shantui Bulldozer yokuPhakamisa iKit yokuLungisa iSilinda

- Amacandelo e-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- I-Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- I-Shantui Dozer Tilt Cylinder Kit yokulungisa

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- I-Shantui Sd22 Ethwele umkhono

- I-Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Iinxalenye zeNjini yeSinotruk

- Ilori yokutsala

- Izahlulo ze-Bulldozer ze-Xcmg

- Xcmg Bulldozer izahlulo eziSpare

- Xcmg Hydraulic Lock

- Ugqithiso lwe-Xcmg

- Amacandelo eNjini yeYuchai