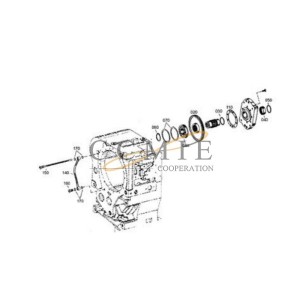

Umlayishi wamavili we-rocker iinxalenye ze-XCMG Liugong umlayishi wamavili

iroki

Kuba zininzi iintlobo zeendawo ezisecaleni, asikwazi ukuzibonisa zonke kwiwebhusayithi. Nceda uzive ukhululekile ukuqhagamshelana nathi ukuze ufumane ezinye.

inzuzo

1. Sinikezela ngeemveliso zoqobo kunye nezasemva kwentengiso kuwe

2. Ukusuka kumvelisi ukuya kumthengi ngokuthe ngqo, ukugcina iindleko zakho

3. Isitokhwe esizinzileyo seendawo eziqhelekileyo

4. Ngexesha lokuHanjiswa kweXesha, kunye neendleko zokuthumela ezikhuphisanayo

5. Ubungcali kunye nexesha emva kwenkonzo

ukupakisha

Iibhokisi zeebhokisi, okanye ngokwesicelo sabathengi.

inkcazelo

Umsebenzi wetappet kukudlulisa ukutyhala kwecam kwintonga yokutyhala okanye intonga yevalvu, ukutyhala intonga yokutyhala okanye ivalve ukoyisa amandla entwasahlobo yevalve, kwaye kwangaxeshanye ithwale amandla asecaleni akhutshwa yicamshaft xa iyajikeleza. Isikhundla sofakelo ngumngxuma wesikhokelo ubhorekile kwindawo ehambelanayo yebhloko yesilinda okanye intloko yesilinda, edla ngokwenziwa ngentsimbi ye-nickel-chromium yealloy okanye i-cold shock alloy cast iron.

1)Iitapethi eziqhelekileyo Zintathu iindidi zeetapethi eziqhelekileyo: iitapethi ezimile okwefungus, iicylindrical tappets kunye neroller type tappets. I-fungus-shaped and cylindrical tappets inokunciphisa ubunzima babo ngenxa yefom engenanto; i-roller-type tappets idibene nomgca ngenxa yefom yoqhagamshelwano, kwaye i-roller inokuqengqeleka ngokukhululekileyo, enokunciphisa ukunxiba. Iitephu eziqhelekileyo zizakhiwo eziqinileyo kwaye azikwazi ngokuzenzekelayo ukucima ukucocwa kwevalvu. Ke ngoko, iinjini ezisebenzisa iitephu eziqhelekileyo kufuneka zilungelelanise ukucocwa kwevalvu.

2)Iimpawu zeetapethi zehydraulic: Olona ncedo lukhulu lweetapethi zehydraulic ngaphezu kweetephu eziqhelekileyo kukuba zinokuphelisa ukucocwa kwevalve ye-injini ngaphandle kokulungelelanisa ukucoceka kwevalve; Kwangaxeshanye, iitapethi zehydraulic zinokunciphisa ingxolo yosasazo yendlela yesivalo se-injini.

3) Ubume betappet ye-hydraulic: umzimba we-tappet udityaniswe kumzimba omnye ngesigqubuthelo esingaphezulu kunye ne-cylinder, kwaye unokunyuka usehla kumngxunya we-tappet wentloko yesilinda. Umngxuma wangaphakathi kunye nesangqa sangaphandle somkhono zombini zigqityiwe kwaye ziphantsi. Isangqa sangaphandle sihambelana nomngxuma wesikhokelo kwi-tappet, kwaye umngxuma ongaphakathi uhambelana neplunger. Zombini zinokushukuma xa zithelekisana. Imithombo yembuyekezo ifakwe emazantsi ecylinder yehydraulic ukucinezela ivalve yebhola kwisitulo sevalve seplunger. Inokugcina umphezulu wetappet unxibelelana ngokusondeleyo nomphezulu wecam ukuphelisa ukukhutshwa kwevalvu. Xa i-valve yebhola ivala umngxuma ophakathi we-plunger, i-tappet inokwahlulwa ibe ngamagumbi e-oyile amabini, i-oyile ephezulu yoxinzelelo oluphantsi kunye ne-oyile ephantsi yoxinzelelo oluphezulu; emva kokuba ivalve yebhola ivuliwe, i- through the chamber yenziwa.

4) Umgaqo osebenzayo wetappet ye-hydraulic Xa i-oyile ye-annular groove kumzimba we-tappet ihambelana nomngxuma weoli oblique kwintloko ye-cylinder, i-oyile ekwinkqubo yokuthambisa i-injini iqukuqela kwi-oyile yoxinzelelo oluphantsi ngomngxuma oyile oblique kunye ne-annular. i-oyile. I-groove engundoqo ngasemva kumzimba we-tappet inokukhokelela ioyile kwindawo yoxinzelelo oluphantsi lweoyile ngaphezulu kweplunger. Xa i-cam ijikeleza kwaye umzimba we-tappet kunye ne-plunger ihambela ezantsi, i-oyile ekwigumbi le-oyile yoxinzelelo oluphezulu iyaxinzelelwa kwaye uxinzelelo lweoyile luyenyuka. Kunye nentlakohlaza yembuyekezo, ivalve yebhola icinezelwe ngokuqinileyo kwisitulo esisezantsi sevalve yeplunger. Xa i-oyile ye-high-high-pressure ihlukaniswe kwigumbi leoli eliphantsi. Ngenxa yokuba ulwelo lungenakucinezeleka, yonke i-tappet yehla njenge-cylinder, ityhala isikhondo sevalve sivuleke. Ngeli xesha, i-tappet annular oil groove iye yaxutywa kunye ne-oblique oil hole, kwaye i-oil intake iyayeka. Xa i-tappet ifikelela kwiziko layo elisezantsi elifileyo kwaye iqala ukunyuka phezulu, phantsi kwesenzo se-valve ephezulu kunye noxinzelelo olusezantsi lwekhamera, i-oyile yoxinzelelo oluphezulu ivaliwe kwaye i-valve yebhola ayiyi kuvuleka. I tappet yehydraulic isenokuthi ithathwe njenge tappet eqinileyo ide iphakame. Kuze kube yikhamera kwisangqa sesiseko kunye nevalve ivaliwe. Ngeli xesha, ioyile yoxinzelelo kwipaseji yeoyile ephambili yentloko yesilinda ingena kwigumbi leoyile yoxinzelelo oluphantsi lwetappet ngomngxuma oyile othambekele. Kwangaxeshanye, uxinzelelo lwe-oyile kwigumbi loxinzelelo oluphezulu luyehla, kwaye umthombo wembuyekezo utyhala i-plunger phezulu. I-oyile yoxinzelelo olusuka kwi-oyile ye-oyile ephantsi ityhala ivule i-valve yebhola kwi-high-pressure oil room, ukwenzela ukuba amagumbi amabini adibaniswe kwaye azaliswe ngeoli. Ngeli xesha, umgangatho ophezulu we-tappet usanxibelelana ngokusondeleyo nekhamera. Xa i-valve ishushu kwaye yandiswa, i-plunger kunye ne-cylinder ye-hydraulic ihamba ngokuhambelana nomnye kwicala le-axial, kwaye i-oyile ekwigumbi le-oyile yoxinzelelo oluphezulu inokucinezela kwigumbi le-oyile eliphantsi koxinzelelo ngesithuba phakathi kwe-cylinder ye-hydraulic. kunye ne-plunger. Ke ngoko, xa usebenzisa iiteyipu zehydraulic, akukho mfuneko yokuba ugcine ivalve clearance.

2. Umsebenzi wentonga yokutyhala kukudlulisa ithraphu egqithiselwa ukusuka kwicamshaft ngetappet ukuya kwingalo yerocker kwindlela yokuhambisa umoya yevalve ephezulu kunye necamshaft esezantsi. Intonga yokutyhala yeyona nto iguquguqukayo kwaye ibhityile kuloliwe wevalvu. Ubume bayo ngokubanzi bubandakanya iinxalenye ezintathu: intloko yebhola ye-concave ephezulu, intloko yebhola ephantsi ye-convex kunye nentonga engenanto. Intonga yokutyhala iqhele ukwenziwa ngombhobho wentsimbi ongenamthungo otsaliweyo, kwaye ezinye zenziwe ngeduralumin. I-putter yensimbi eqinile yenziwa ngokubanzi kunye nenkxaso ye-spherical, kwaye emva koko iphathwa ngobushushu; iziphelo ezimbini ze-duralumin eziphathekayo i-putter eqinile zixhotyiswe ngeenkxaso zetsimbi, kwaye iziphelo eziphezulu kunye nezantsi zihlanganiswe ne-shaft; intloko yebhola yangaphambili kunye ne-Shaft ifakwe ngokupheleleyo, kwaye iziphelo ezimbini zokugqibela zihlanganiswe kunye ne-shaft nge-welding kunye ne-press-fitting. Nangona kukho ukungafani okuthile kwifom yesakhiwo, iimfuno zentonga yokutyhala ziyafana, oko kukuthi, ubunzima obulula kunye nokuqina okuphezulu. Phantsi kweemeko eziqhelekileyo, ukuze kuqinisekiswe ukufaneleka okuchanekileyo kwetappet, ingalo yerocker kunye netappet, intsimbi yeconcave spherical joint idityaniswe kumphezulu wentonga yokutyhala ukuze itshatise intloko yebhola ye-rocker arm adjusting screw; Kwisokethi yebhola yeconcave.

3. Umsebenzi ophambili wengalo ye-rocker kukutshintsha indlela yokuhanjiswa kwamandla. Ingalo ye-rocker ilingana nesakhiwo se-lever, esithumela amandla entonga yokutyhala ukuya ekupheleni komsila wesiqu sevalve ukutyhala ivalve ukuba ivuleke; Umlinganiselo wobude beengalo ezimbini (ebizwa ngokuba yi-rocker arm ratio) isetyenziselwa ukutshintsha ukunyuswa kwevalve, ingalo yevalve yeroki Ngokubanzi, yenziwa ngohlobo lobude obungalinganiyo. Ingalo ekwicala levalvu ngama-30% ukuya kuma-50% ubude kunengalo ekwicala lentonga yokutyhala, ukuze kufunyanwe ukunyuswa kwevalve enkulu.

Indawo yethu yokugcina impahla1

Pakisha kunye nenqanawa

- I-Aerial Boom Lift

- Ilori yokulahla i-China

- I-Recycler ebandayo

- I-Cone Crusher Liner

- Isingxobo Side Lifter

- Inxalenye ye-Dadi Bulldozer

- I-Forklift Sweeper Attachment

- Izahlulo ze-Bulldozer ze-Hbxg

- Iinxalenye zeNjini yeHowo

- Hyundai Excavator Hydraulic Pump

- Iinxalenye zeKomatsu Bulldozer

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Izahlulo zeBulldozer yaseLiugong

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Amacandelo eNjini yaseShacman

- Shantui Bulldozer Clutch Shaft

- I-Shantui Bulldozer iQhagamshela i-Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- I-Bulldozer ye-Shantui Bulldozer yokuPhakamisa iKit yokuLungisa iSilinda

- Amacandelo e-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- IShantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- I-Shantui Dozer Tilt Cylinder Kit yokulungisa

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- I-Shantui Sd22 Ethwele umkhono

- I-Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Iinxalenye zeNjini yeSinotruk

- Ilori yokutsala

- Izahlulo ze-Bulldozer ze-Xcmg

- Xcmg Bulldozer izahlulo eziSpare

- Xcmg Hydraulic Lock

- Ugqithiso lwe-Xcmg

- Amacandelo eNjini yeYuchai